■ For Explosion-Proof

▶ Summary System

Industrial machinery within hazardous areas, semiconductor • LCD manufacturing equipment, since is applied to protect expensive equipment such as a chemical liquid supply system from the fire, the automatic fire extinguishing system made for the purpose of perfect initial fire fighting, reliable fire safety system

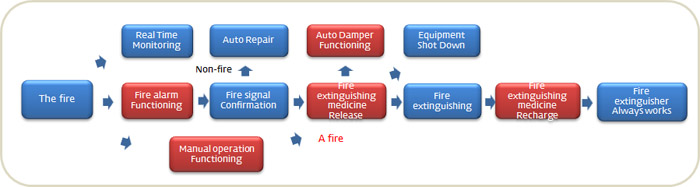

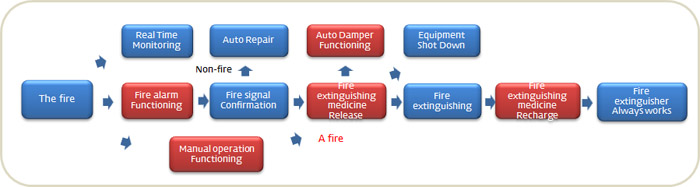

▶ Flow of System

▶ Features System

- Depending on the motion of fire extinguisher, user can choose operation way automatically or manually.

- All monitoring operation status is displayed on the LCD control panel and all contents would be stored in inside IC memory chip. (Whenever user can see it)

- Easy to know the status of the machine by showing LED, ALARM of abnormal part.

- Monitoring lamp for daily power and emergency power in case of power failure changes automatically to monitor fire possible(About 60 minutes)

- All monitoring operation situation, it is possible to monitor the disaster prevention center through the RS-485 communication.

- Selection of protective gas applied to the interior of the fire extinguisher is possible. (N2, AIR)

- Convenient to maintain the inside pressure of fire extinguisher thanks to pressurization with leakage compensation .

▶ Specifcation

| Model |

NEX-1EG0141 |

NEX-2EG0231 |

NEX-3EG0461 |

Size

(mm) |

W |

500 |

400 |

570 |

| D |

337 |

379 |

379 |

| H |

1,120 |

1,570 |

1,570 |

| Weight |

76kg |

110kg |

182kg |

| Extinguishing

Containers |

14kg x 1BOTTLE |

23kg x 2BOTTLE |

23kg x 2BOTTLE |

| Extinguishing

Agents |

CO2,HFC-23,HFC-227ea(Optionally Available) |

| Protective Gas Temperature |

Lower than 40 ℃ |

| Power |

DC 24V |

| Certification Standards |

Pz Pressure Explosion-Proof Structure |

| Explosion Proof Level |

Ex pz II T6 |

| Pressure Maintenance Method |

Leakage Compensation Pressurization Method |